Technology, innovation and quality in industrial processes

Availing of machinery and the latest technology and thanks to the flexibility of its production cycle, SITA Compositi is able to create products in composite materials of various sizes and for different applications, with mechanical properties satisfying any customer requirement

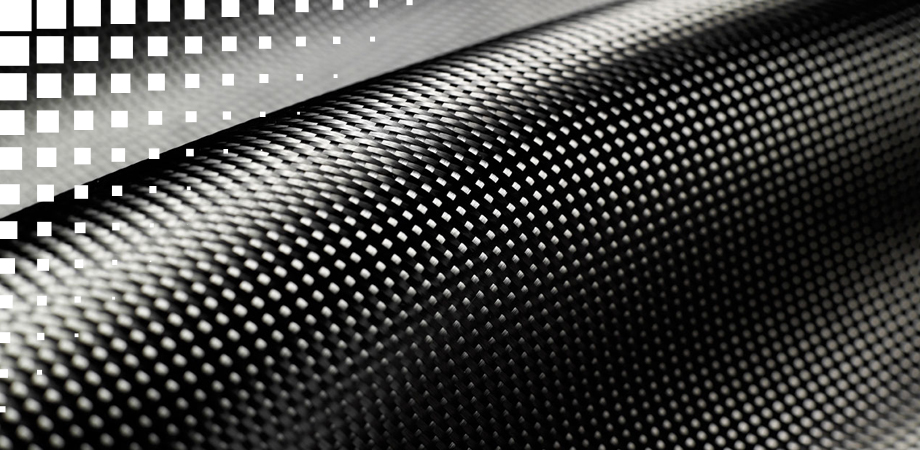

Wrapping technology

The Wrapping technology, used by SITA Compositei s.r.l. specifically for the manufacture of rollers and cylinders, consists in winding layers of fabric made of carbon fiber, or other composite material, with different properties of elastic modulus and strength, over steel spindles of the desired diameter and length.

This distinction is aimed at obtaining different stiffnesses depending on the technical specifications required by the customer and based on the type of application.

The rollers of SITA Compositi, in fact, can be composed of a minimum of three layers of pre-impregnated sheets up to several tens, rolled on a cylindrical element, following procedures certified by specific work cycles.

Autoclave

The polymerization step is performed exclusively in an autoclave at a temperature of 140 ° C and at a pressure of 5 bar.

the autoclave process is used to remove any empty spaces in the material and compact it.

This technique further increases the quality and the mechanical properties of the artefact of SITA Composites.

Vacuum bag technology

SITA Compositi s.r.l is able to make products of any shape: sheets, design objects, parts for machines, characterized by exceptional stiffness, excellent bending strength and at the same time extraordinary lightness, for applications in the most diverse sectors.

For the production of artefacts other than those of tubular shape, SITA Compositi uses the technology of the vacuum bag, which consists in the stratification of the tissues of prepregs on appropriate molds, suitably treated with release agents.

The fabrics laminated on the molds are then closed inside of bags where they are polymerized, under pressure and under vacuum in an autoclave. After the cycle of “compaction”, the bag is opened, pulling the piece and making the necessary mechanical machining (cutting to size, sanding, etc..).