25 years of innovation in the name of tradition

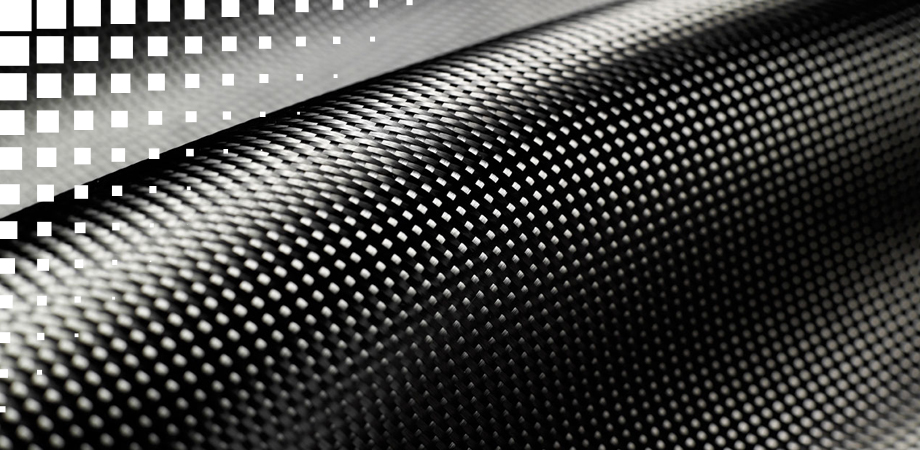

Innovation, competitiveness and quality certifications have always characterized the work of SITA Compositi s.r.l., founded by SITA Società Italiana Tecnologie Avanzate s.r.l., and now a leader in the processing and production of tubular shapes, slabs and semi-finished composite material reinforced with carbon fiber, fiberglass, kevlar or alutex and with epoxy resin matrix.

The carbon core in the heart of SITA Compositi

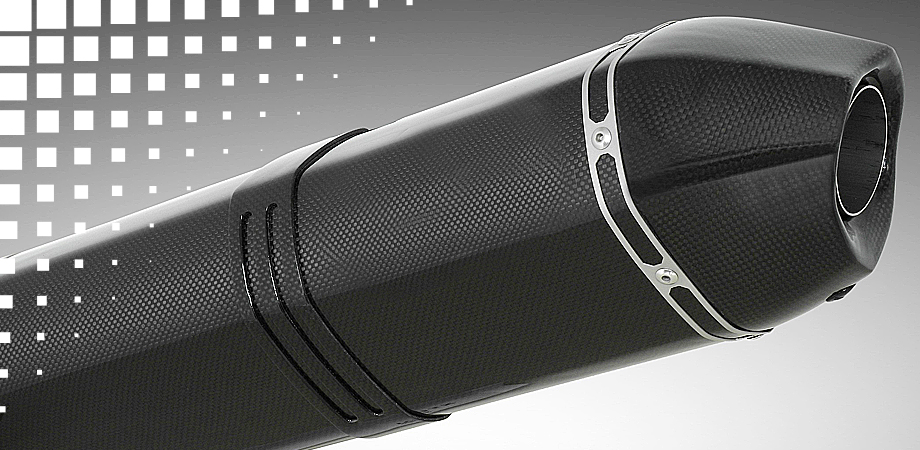

In twenty-five years of activity, SITA Compositi has established important partnerships with different business realities and has specialized in the production of carbon rollers and cylinders for industrial applications that require high-level performance and high speeds.

The structures made of carbon fibers, with the same mechanical characteristics, weigh about 5 times less than traditional steel and this makes all applications advantageous where the lightness factor is decisive.

Advanced solutions for industrial applications

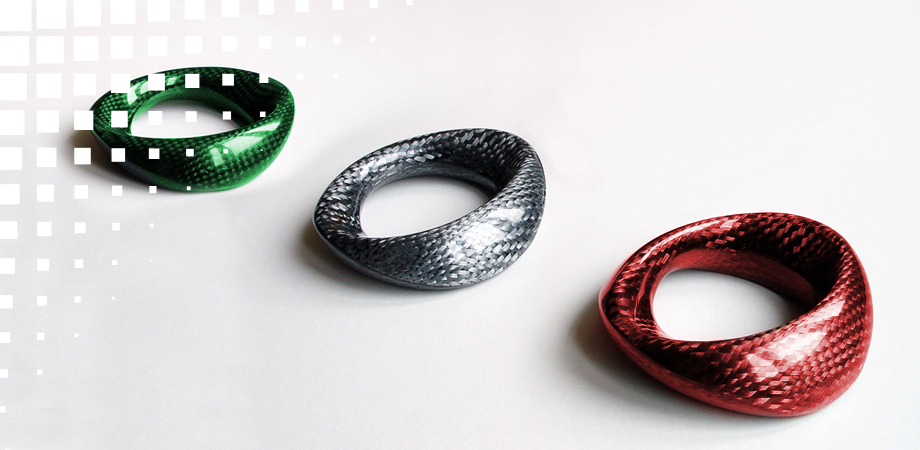

Making use of the latest generation of technological supports, SITA Compositi s.r.l. is able to produce custom pipes and rollers and artefacts of any shape with mechanical properties that satisfy customers requirements and characterized by exceptional stiffness, excellent bending strength and at the same time extraordinary lightness, for applications in different fields.

Quality as choice and goal to be pursued

SITA Compositi s.r.l. adopted a provision system which, combined with the technology used in the different stages of processing, allows to obtain items with high and constant quality standard.

For SITA Composites s.r.l these elements have become critical business growth factors, which have earned the achievement of quality certification and compliance, according to the criteria established by the UNI EN ISO 9001:2000.

ADVANTAGES OF CARBON ROLLERS

- Less weight (about 5 times less than steel), with a consequent increase of production due to the higher speed of the machinery

- Less vibration due to low mechanical inertia

- Less powerful machines with consequent energy saving

- Corrosion resistance and less wear of mechanical parts with additional savings on maintenance costs

- Very low coefficient of thermal expansion

- Diameters and contact surfaces reduction

- High speeds due to the low inertial mass

![]()